Nyob rau hauv cov txheej txheem machining, nws yog feem ntau ntsib hais tias qhov dimension ntawm machining raug tsis cim.Feem ntau, cov neeg siv khoom yuav piav qhia txog tus qauv siv nrog cov ntawv nyeem ntawm daim duab.Tau kawg, txhua lub teb chaws thiab cheeb tsam muaj nws tus kheej tus qauv, tab sis cov qauv sib xws yog raws li hauv qab no:

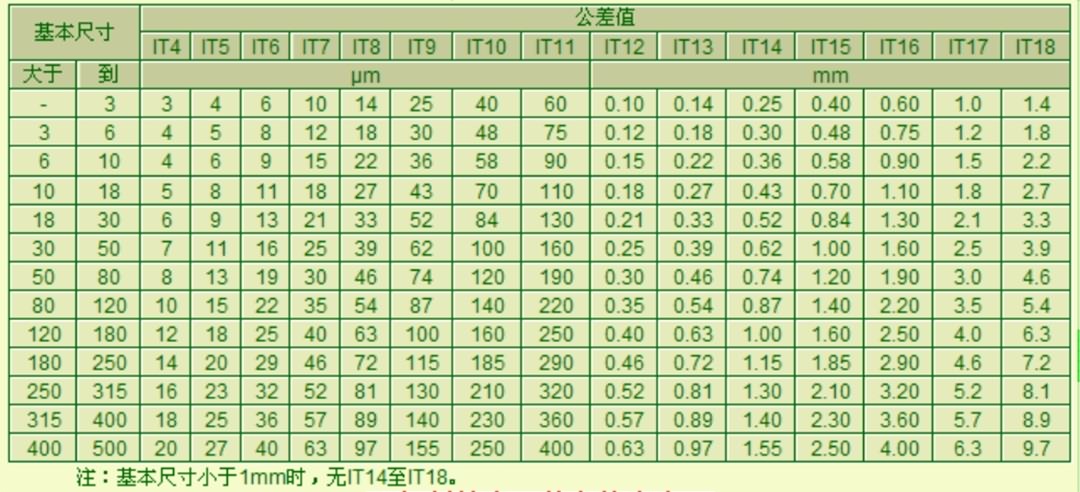

Thawj yog raws li tus txheej txheem thoob ntiaj teb.Cov nram qab no yog cov qauv kam rau ua ntawm 0-500mm yooj yim dimension nrog qhov tseeb theem 4 txog 18:

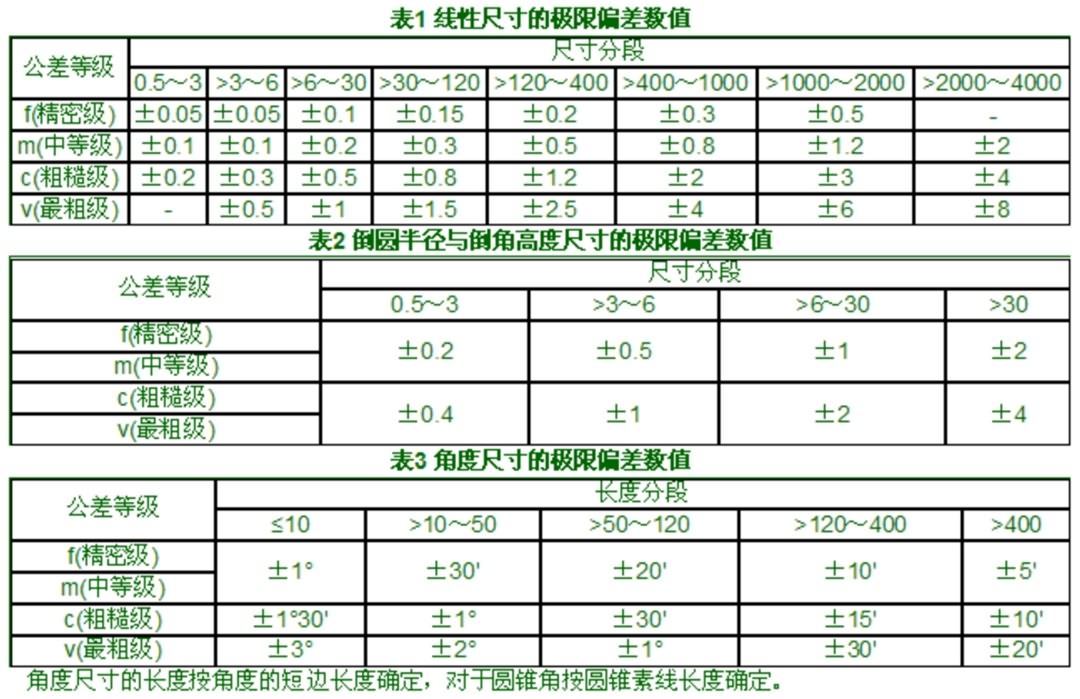

Raws li tus txheej txheem thoob ntiaj teb, qhov thib ob yog tsim rau kev txiav hlau thiab kev ua haujlwm stamping

Linear Dimension: sab nrauv, sab hauv qhov ntev, kauj ruam loj, txoj kab uas hla, vojvoog, nrug, thiab lwm yam

Lub kaum sab xis: ib qhov ntev uas feem ntau tsis qhia lub kaum sab xis, piv txwv li, lub kaum sab xis ntawm 90 degrees

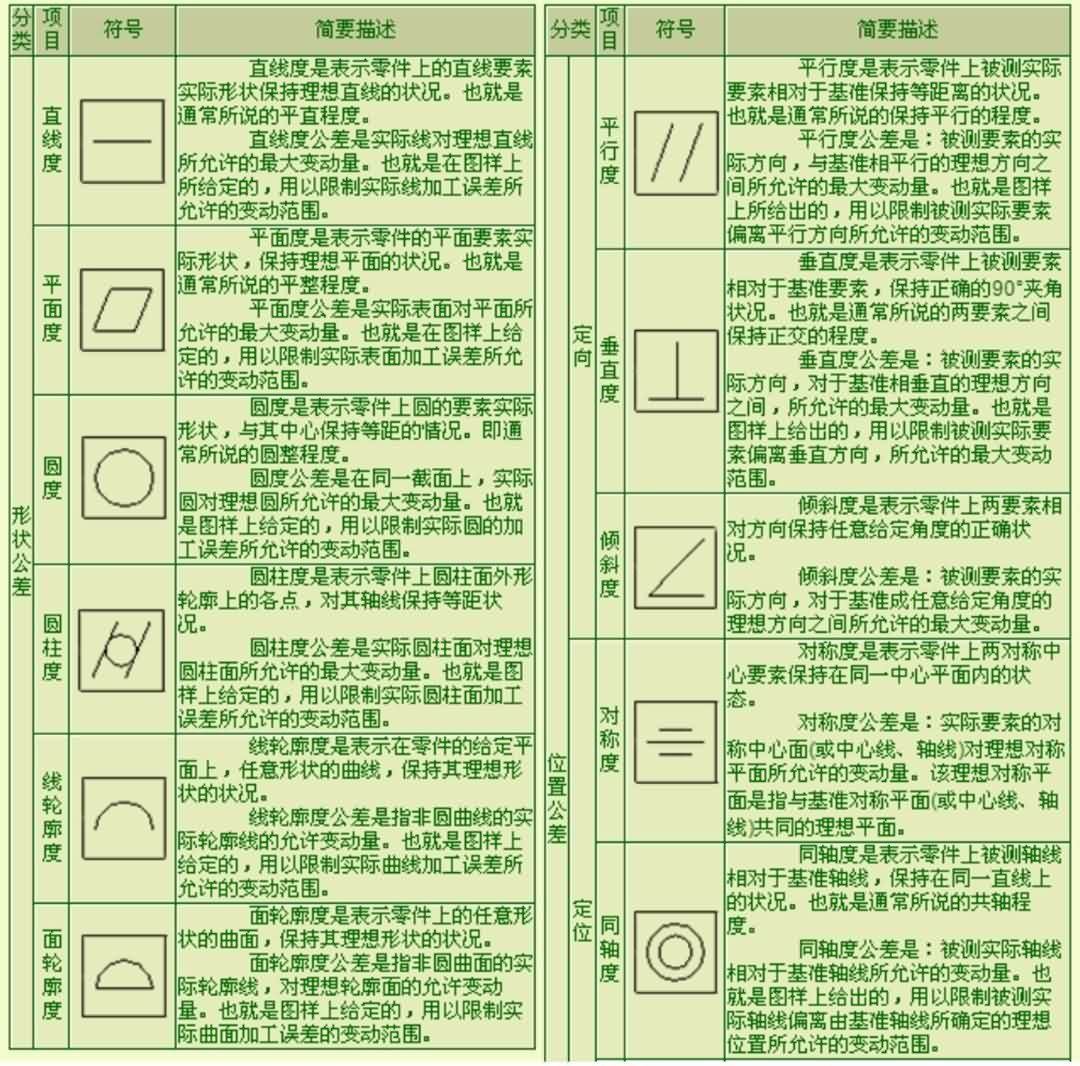

Cov duab kam rau ua yog hais txog tag nrho cov kev hloov pauv tau tso cai los ntawm cov duab ntawm ib qho tshwj xeeb tiag tiag, uas yog qhia los ntawm cov duab kam rau ua cheeb tsam, uas suav nrog plaub lub ntsiab ntawm kev kam rau siab, kev taw qhia, txoj hauj lwm thiab qhov loj me;Cov khoom zoo siab muaj xws li ncaj, flatness, roundness, cylindricity, profile ntawm kab, profile ntawm lub log tiaj tus, thiab lwm yam.

Txoj hauj lwm kam rau ua muaj xws li orientation kam rau ua, positioning kam rau ua thiab runout kam rau ua.Saib cov lus hauv qab no kom paub meej:

Post lub sij hawm: Oct-12-2020